Packing range(bag size) Width 100-200mm, Length 100-300mm

Packing Weight ≤ 500ml

Capacity 30-50 bag/min (speed depends on filling product &weight)

Packing Precision error<±1%

Pouch type Stand-up bag,Flat bag, paper bag,composite material etc.

Total Power 2 kw

Compressed Air Consumption 0.6 m3/min

Voltage 3 Phase 380V 50HZ/60HZ

Total Size (L)2420*(W)1510*(H)1480mm

Machine Weight 800 kg

Bags type: Zipper bag/stand up pouch/three or four sides sealing bag

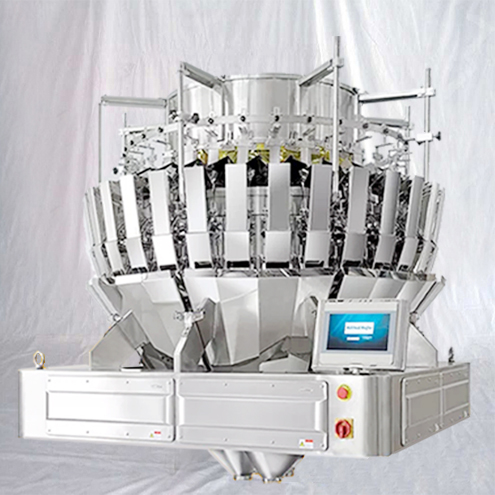

automatic doypack pouch liquid packing machine bags-given packaging equipment for premade bags

Application of juice filling sealing machine model YX-08-300ML:

The machine is widely used in foods, chemicals, pharmaceuticals, seeds and other industrial fields, such as juice, ketchup, detergent, etc.

The honey packing machine production line can be fully automatic operated;

It can achieve product packing assembly line work, and improve production efficiency and significantly reduce product cost.

The honey packing machine production line conforms to the food processing machinery's sanitation standard. On the machine, the spare part which contacts with the material and pouch conforms to the standard of food sanitation

request on material processing, food health and security guarantee.

This honey packing machine production line is suitable for the packing liquid, the hydrodynamic material, such as detergent, yellow wine, soy sauce, vinegar, fruit juice, ketchup, peanut thick liquid, jam, hot pepper sauce, thick bean sauce packed in bags.

Feature of packing equipment:

1. Easy to operate. The machine with Japan Mitsubishi PLC control, man-machine interface with touch screen control system, it can be operate easily.

2. Frequency control. The machine with frequency control, the required speed can be adjustable within the range according to any needs of reality in production.

3. Automatic detection. No pouch or pouch is not opened completely, no feeding, no sealing, pouch can be reused, avoid wasting materials, it can reduce production costs for user.

4. Safety devices, when the abnormal pressure of work or failure of heating pipe, it will alarm.

5. The width of the bags could be adjusted by electrical motor. Press the control-button could adjust the width of clips, easily operate, and save time.

6. Part of plastic bearings are imported, no oil, reduce pollution materials.

7. Use no oil vacuum pump, avoid polluting the environment in the production.

8. The packing materials loss low, what this machine is used the preformed bag,the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification.

Main parameter of bags given pouch packing machine :

| Model | YX-08-300ML |

| packing range | Width 100-200mm, Length 100-300mm |

| filling volume | 500ml |

| Capacity | 30-50 bag/min (speed depends on filling product &weight) |

| Precision | Discrepance <±1% |

| Pouch Type | Stand-up bag,Flat bag, paper bag,composite material etc |

| Total Power | 2.1KW |

| Air Consumption | 0.6m3/min |

| Voltage | 3 Phase 380V 50HZ/60HZ(USA power supply customized) |

| Machine Size | (L)2420*(W)1510*(H)1480mm |

| Weight | 800kg |

| Note |

1.According to the customer request,provides the special design. 2.The machine disposition may make the choice. |

Different working station for different sizes bags &filling materials:

|

Working Station |

6 |

8 |

8A |

8B |

|

|

Pouch size |

Normal pouch |

For double filling (such as liquid and granule) |

For stand up pouch (bottom is thicker than 0.1mm) |

For zipper bag |

|

|

Pouch material |

Laminated film |

||||

|

Pouch pattern |

Stand up pouch, flat pouch etc |

||||

|

Speed |

30-60pouches/min |

||||

|

Voltage |

380V 3PH 50HZ/60HZ |

||||

|

Compress air |

0.6m3/min(supply by user) |

||||

Machine details for bag-given packing process:

Bag sealing samples:

Different materials decide different metering way for bags-given packing machine:

Powder&granules listed as below respectively:

Wooden case for pouch filling sealing machine:

Services of liquid detergent pouch bags given packing machine:

1. Pre-sale service : according to customer's requirement , we can supply the factory drawing picture. and suggestion for building the factory.

|

The common failures and troubleshooting methods |

|||

|

|

|||

|

9.1No electricity |

1.Power supply wire break; |

Replace the wire; |

|

|

2.Air switch automatic tripping; |

Air switch is damaged, replace the air switch; |

||

|

Have the leakage or short circuit phenomenon, check and solve it |

|||

|

9.2Suction bag effect is poor |

1.Vacuum suction cups with dust or damage; |

Replace the sucker; |

|

|

2.Vacuum filter clogging; |

Clean and replace; |

||

|

9.3Bag on the bad |

1.On the bags of rugged; |

Adjust the bag warehouse; |

|

|

|

|

||

|

|

|

||

|

2.Bag machine clip crease in edge; |

Adjustment on the bag of manipulator position by 1/3 position before the machine; |

||

|

3.Around bag is rough; |

Adjust the bag warehouse; |

||

|

4.Clip bag is not in place or put too early。 |

Readjust the bag on the parameters。 |

||

|

9.4Code quality is poor |

1.Temperature is set too high or too low; |

Adjusted to the right temperature; |

|

|

2.Damage the electric heating tube; |

Replace the electric heat pipe; |

||

|

3.Code damage of solid state relay; |

Replace the solid state relay; |

||

|

9.5No fewer than expected |

1.The synchronous control point is not correct; |

To readjust the synchronization points; |

|

|

2.Bag of proximity switch is damaged; |

Replace bags proximity switch; |

||

|

3.Blanking line not connected。 |

Through signal lines |

||

|

9.6The sealing quality is poor |

Longitudinal wrinkle |

1.Small bags of tension, enters the sealing relaxation; |

Adjust to open the position of the CAM; |

|

Adjust the bag is flat and level. |

|||

|

2.Machine head is stained with oil. |

Oil cleaning machine clip on. |

||

|

Horizontal crease |

3.Heat sealing temperature is too high |

Regulate the temperature of a heat sealing. |

|

|

The sealing is not completely |

1.The sealing pressure or inadequate; |

Adjust the heat sealing cylinder pressure; |

|

|

2.Two poor contact heating plate; |

Check the contact condition of two heating plate; |

||

|

3.The sealing material; |

Nice as the filling material position adjustment; |

||

Email:

Email: Tel:+8675586718316

Tel:+8675586718316