Our Regular customers from Mexica(South portion of North America) placed another order on one(1*) pcs of machines: Model YX-IP100 irregular bags packing machine high viscosity liquid bagging equipment

For all the machines purchased it is clear to confirm all the information on the products so we often ask our customers to freight the samples to test and commission the machines in order that the machines and customer's products gains the best compatibility and adaptability.

After getting the confirmation &samples of the product in sizes and drawing for manufacturing the filling sealing bagging machines

we spent only 7days finishing everything and made the machines ready after testing them in a satisfactory feedback.

Recently our customers sent us the positive commentar on the machines which keep running very well in their factory ever since the machines arrived their factory.

The machines was shipped via courier to Mexico . The documentaries certificated with ISO&CO&CE together with other files necessory are sent via DHL to customer for assisting customers to clear the custom.

As below there listed the basic information on the successful transaction between PENGLAI and their Mecican counterpart:

Purchased order issued from American customer:

Samples sent from customers in North America

Bank copy of Down&balance payment for purchasing Model YX-IP100 Liquid bagging packing machine

Testing videos on filling bagging liquid machine model YX-IP100

Wooden case packing of liquid packing machine irregular bags packaging equipments.

As follow there given the description on the machines purchased respectively

Irregular shape sachet packing machine liquid packaging machinery for irregular-shaped bags spout

PRODUCT DESCRIPTION on irregular shape bag ffs packaging machinery

1. It can complete automatically make you prefered bag, weigh, fill, seal, cut, print date code, etc.

2. 304 stainless steel machine, PLC computer control system with touch screen, display screen is simple and direct viewing in operation, daily production output and self-diagnostic machine error will be viewed directly from the screen.

3. It adopts sealing mould and cutting mould to keep irregular shaped sachet.

4. Driven type: pneumatic, it make the operation easy than mechanical driven type, and the packing samples more beautiful than common.

5. Attractive appearance. Stable performance.

6. The machine fix stepper motor controller, its advantage is precise, needless to adjust other parts.

7. Intelligent temperature control by temperature controller to make heat balance better.

8. Fine packaging performance, low noise, clear sealing texture and strong sealing performance.

9. With safe plastic box on rotating blade to avoid hurting operators hands.

10. High sensitive fiber optic photo sensor can automatically trace color mark accurately.

main technical parameters and configurations of irregular bags packing machinery PENGLAI Brand:

| model number | YX-IP30 YX-IP100 |

| speed | 20-50bags/min 20-35Bags/min |

| range | 1-50ml 50-200ml |

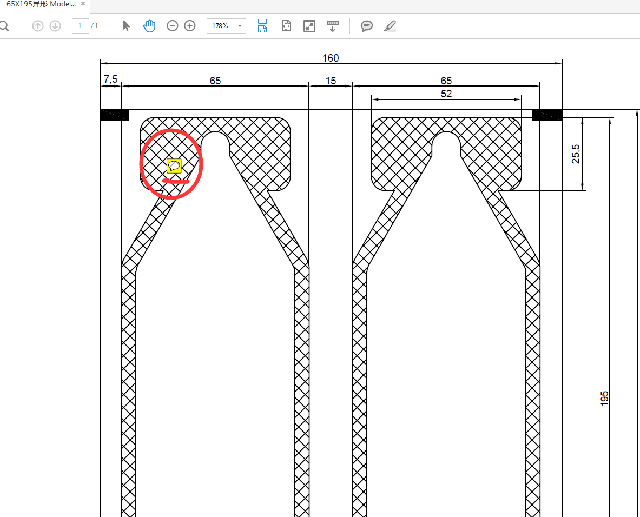

| bag size |

L 50-140mm L50-200mm W 25-80mm W25-110mm |

| bag type | irregular shaped, it is design by yourself |

| voltage power | 220V/50-60Hz 2KW Power :2.5KW |

| packaging material | paper, PE, PET, AL oil, any laminated film |

| N.W | 320KG 450KG |

| dimension | 1930x750x1800mm(LxWxH) 2130x850x1800 |

| PLC | Omron |

| temperature control | Omron |

| servo motor | Schneider |

| power | Schneider |

| display | Siemens |

|

Packing Materials:Paper/PE,PET/AL Foil/PE,PET/PE,Nylon/PE, Tea-leaf filtering paper etc |

|

Packaging pictures about our machine exported

After-sale service for packaging machinery irregular bags model YX-IP100

Guarantee: for all the machine, it claims three years for guarantee.(Excluded from the warranty are problems due to accidents, misuse , misapplication, storage damage, negligence, or modification to the Equipment or its components. ALSO THE EASY BROKEN SPARE PART IS NOT INCLUDED IN THE GUARANTEE)

Installation: after the machine arrive your factory,if you need,our technician will go to your place to install and test the machine and also training your worker to operating the machine (The time of train depend on you worker). The expenses (air ticket ,food , hotel,the travelling fee on your country) should be on your account and you need paid for the technician USD50 per day. also you can go to our factory to do training.

After service: If you get the problem on the machine ,our technician will go to your place to fixed the machine as soon as possible . The cost should be in your account.(as above).

Email:

Email: Tel:+8675586718316

Tel:+8675586718316